|

44.18 Builders’ joinery and carpentry of wood, including cellular wood panels, assembled flooring panels, shingles and shakes.

This heading applies to woodwork, including that of wood marquetry or inlaid wood, used in the construction of any kind of building, etc., in the form of assembled goods or as recognisable unassembled pieces (e.g., prepared with tenons, mortises, dovetails or other similar joints for assembly), whether or not with their metal fittings such as hinges, locks, etc.

The articles of this heading may be made of ordinary wood or of particle board or similar board, fibreboard, laminated wood or densified wood (see Note 3 to this Chapter).

The term "joinery" applies more particularly to builders’ fittings (such as doors, windows, shutters, stairs, door or window frames), whereas the term "carpentry" refers to woodwork (such as beams, rafters and roof struts) used for structural purposes or in scaffoldings, arch supports, etc., and includes assembled shuttering for concrete constructional work. However, plywood panels, even if surface treated for the purposes of concrete shuttering, are classified in heading 44.12.

Builders’ carpentry also includes glue laminated timber (glulam), which is a structural timber product obtained by gluing together a number of wood laminations having their grain essentially parallel. Laminations of curved members are arranged so that the plane of each lamination is at 90 degrees to the plane of the applied load; thus, laminations of a straight glulam beam are laid flat.

This heading also covers cellular wood panels which are somewhat similar in appearance to the blockboard and battenboard described in the Explanatory Note to heading 44.12, but the battens or laths forming the core are spaced one from the other, either parallel or in lattice form. In certain cases the panels may consist of facing sheets separated by an internal frame at the edges only. The interstices may be packed with sound insulating or heat resisting materials (e.g., cork, glass wool, wood pulp, asbestos). The facing sheets may be of solid wood, particle board or similar board, fibreboard or plywood, and the panels (like those in heading 44.12) may be faced with base metal. Panels of this kind are relatively light but strong and are used for partitions, doors and sometimes in the manufacture of furniture.

This heading also covers solid blocks, strips, friezes, etc., assembled into flooring panels (including parquet panels) or tiles, with or without borders. It also includes flooring panels or tiles consisting of blocks, strips, friezes, etc., assembled on a support of one or more layers of wood, known as "multilayer" parquet flooring panels. The top layer (wear layer) is commonly made from two or more rows of strips making up the panel. These panels or tiles may be tongued and grooved at the edges to facilitate assembly.

A shingle is wood sawn lengthwise which is generally thicker than 5 mm at one end (the butt) but thinner than 5 mm at the other end (the tip). It may have its edges resawn to be parallel; its butt may be resawn to be at right angles to its edges or to form a curve or other shape. One of its faces may be sanded from the butt to the tip or grooved along its length.

A shake is wood split by hand or machine from a bolt or block. Its face reveals the natural texture of the wood resulting from the splitting process. Shakes are sometimes sawn lengthwise through their thicknesses to obtain two shakes, each then having a split face and a sawn back.

The heading does not cover :(a) Plywood panels, veneered panels or panels of similar laminated wood, used as flooring panels, which have a thin veneer of wood affixed to the surface so as to imitate an assembled flooring panel of heading 44.18 (heading 44.12). (b) Cupboards, with or without backs, even if designed to be nailed or otherwise secured to the ceiling or wall (heading 94.03). (c) Prefabricated buildings (heading 94.06). Subheading Explanatory Notes. Subheading 4418.74

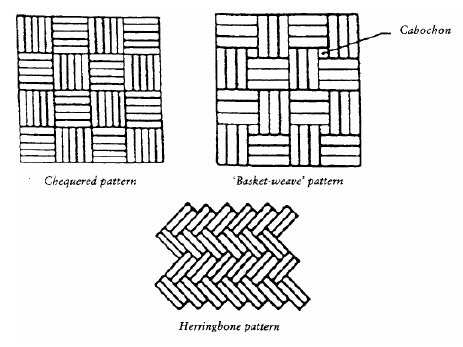

Assembled flooring panels for mosaic floors are prefabricated panels composed of a number of separate square or rectangular elements and possibly including "cabochons" (small square, rectangular, triangle, diamond or otherwise shaped wooden pieces used as fillers to attain the desired pattern). The strips are laid out according to a certain pattern, e.g., chequered, "basket-weave" and herringbone (see examples below).  |

Subheadings 4418.81, 4418.82, 4418.83 and 4418.89

For the purpose of these subheadings, the term "Engineered structural timber products" applies to products consisting of laminated timber or a combination of wood products, such as timber, laminated veneer lumber, plywood or Oriented Strand Board (OSB), to provide greater strength than just sawn timber (heading 44.07). These manufactured products are designed to support the structural load of a building.

Glue-laminated timber (Glulam) is a massive structural member constructed of multiple layers of timber that are glued together with the grain of each layer oriented parallel to those of the successive layers.

Cross-laminated timber (CLT, also referred to as X-lam or cross-ply timber) is a large structural building panel constructed of at least three layers of wood laminated together. Each layer is constructed of multiple solid timber boards (wood sawn or chipped lengthwise, sliced, or peeled, with a thickness exceeding 6 mm) that have been placed side by side, whether or not glued together. The wood grain of each layer is typically oriented at a right angle to the grain of adjacent layers.

CLT is distinct from plywood as it is constructed from multiple pieces of solid sawn timber oriented in layers rather than sheets of veneer (which have a thickness not exceeding 6 mm). The alternating grain construction provides greater structural rigidity in both lengthwise and crosswise directions and provides structural support in load-bearing applications.

I-Beams (also called I-joists) are "I" shaped engineered wood structural members and are comprised of top and bottom flanges (horizontal members), united with webs (vertical members). The flange material is typically laminated veneer lumber (LVL) or solid sawn timber, and the web is made with plywood or oriented strand board (OSB).

|