|

70.19 - Glass fibres (including glass wool) and articles thereof (for example, yarn, rovings, woven fabrics).

This heading includes glass fibres themselves and glass fibres (including glass wool as defined in Note 4 to this Chapter) made up in various forms, including those glass fibre articles excluded from other headings by reason of their nature.

Glass fibres have the following properties : they are less flexible than vegetable or animal textile fibres (glass yarns cannot be knotted easily); they are strong (stronger than any of the textile fibres of Section XI, and in terms of tensile strength they are stronger than steel with less weight); they do not stretch or shrink, offering a good dimensional stability; they are non-hygroscopic; they do not burn and have low sound and thermal conductivity (in some cases); they do not rot and are resistant to water and most acids; they have low UV sensitivity; they are poor conductors of electricity and have dielectric permeability; they are compatible with organic matrices.

Glass wool (random oriented fibres) are glass products in which the filaments are randomly oriented, forming a bulky product, mostly used for insulation purposes.

There are two types of glass fibre:(a) (continuous) filament glass fibre consisting of a large number of continuous parallel filaments with diameters usually between 3 and 34 μm (microns); after forming, those continuous filaments are held together in a strand (a process also called "sizing") designed to facilitate subsequent production steps (chopping, winding, twisting, weaving, etc.). (b) discontinuous glass fibre (staple glass fibre) consisting of filaments cut or broken in short lengths during production process and pulled into a continuous strand of loosely assembled fibres.

Glass fibres can be further processed into the following articles of this heading:

- mats and scrims with chemically bonded fibres, i.e. chopped strand mats, continuous strand mats and typical fabrics which are not woven, like veils (thin sheets), laid scrims, etc.,

- fabrics and mats with mechanically bonded fibres, i.e. woven fabrics, non-crimp fabrics, knitted fabrics, stitched fabrics, needled fabrics like woven roving, open mesh fabrics, screens, etc.

Glass fibres can be obtained by various processes which, apart from a few exceptions, can be grouped in three broad categories :(Ⅰ) Mechanical drawing.

In this process a mixture of sand, limestone and kaolin is melted in a furnace to produce glass. Depending on the composition different glass types may be produced. It flows into a forehearth, the underside of which is fitted with bushings made of alloys of precious metal (normally of rhodium or of platinum) to withstand the high temperatures. The bushings are pierced by a large number of small holes through which molten glass filaments flow. After a sizing treatment (for example, with silicone), the formed strands are either carried on to a high speed mandril which draws them on a cardboard tube or directly chopped under the bushing. The obtained glass fibres (chopped strands) can be further processed into mats and fabrics. (Ⅱ) Centrifugal drawing.

In this system, glass melted in pots falls on a refractory clay disc revolving at great speed and fitted along the periphery with a very large number of teeth. The glass adheres to this disc, which is heated by the flame from a furnace, but, at the same time it is drawn into filaments by means of centrifugal force. These filaments are blown on to a stationary table and coiled on to a cooling drum.

This process thus yields short fibres known as glass wool, which is used in bulk without spinning. (Ⅲ) Drawing by means of fluids.

In this process, drawing is achieved by means of jets of high-pressure steam or compressed air blown from either side on to the filaments of molten glass coming from the furnace through a drawing-plate. Under the action of these jets, the filaments are broken into short lengths which are coated with lubricants in the course of manufacture.

The continuous fibres thus obtained are coiled on a drum to form either webs which are used as such (insulation blankets), or staple fibres which can subsequently be spun into yarn.

Fabrics made of glass fibres are usually obtained by production processes which can be grouped in two main categories :(Ⅰ) Chemical binding: (a) Glass veil process, wet or dry laid (b) Laid scrim process. (Ⅱ) Mechanical binding: (a) Weaving process:

Weaving machines, or looms, interlace the warp fibres (lengthwise direction) and filling fibres (weft) according to various weave patterns (plain weave, leno weave, etc.) to form a closed or open fabric structure. (b) Knitting process:

Knitting machines enable planar or tubular fabric structures to be obtained by inter-looping loops of connected fibres using a knitting system in the length direction (warp knitting) or in the width direction (weft knitting). Warp knitting technology is often used to stitch multi-layer fabrics. (b) Other textile industry processes: stitch-bonding, needling, etc.

Fabrics can have a closed structure (such as woven roving or multi axial fabrics) or open (such as woven open mesh fabrics or laid scrims), depending on the technical requirements of the further production stages required to obtain the final product. Closed fabrics are needed for resin impregnation, while open fabrics with a regular open structure are needed to produce mosquito nets or reinforcement mesh for wall repairs, where render or plaster has to flow through the mesh structure.

Glass fibres and articles of glass fibres of this heading may be, in particular, in the following forms :(A) Glass wool in bulk, boards, panels, mattresses made of glass wool. (B) Slivers, rovings, yarn and chopped strands, mats thereof. (C) Mechanically bonded fabrics, including narrow fabrics. (D) Chemically bonded fabrics including veils (thin sheets), or laid scrims. This heading also covers curtains, draperies and other articles of woven glass fabrics.

It is pointed out that although "chemical embroideries" or embroideries without visible ground, in which the embroidering thread consists of glass fibres, are classified here, embroidery in any of the textiles classified in Section XI, in which some of the effects are obtained by embroidering threads made of glass fibres, is excluded (heading 58.10).

The uses of glass fibres and fabrics made of glass fibres are numerous, for example :(1) For infrastructures, environmental use and green energy generation (e.g., multi-axial fabrics reinforcing wind blades, geotextiles for road reinforcement, composites in bridge structure, etc.). (2) In the building and construction sector (e.g., for reinforcement of roofing membranes or shingles, carpets, cement and gypsum boards, architectural textiles, facade cladding, wall repair and external thermal insulation composite systems, etc.). (3) In furnishing and interior decoration (e.g., for upholstery, wall hangings, curtains, mosquito nets, sun screens), in the form of fabrics, which can be dyed or printed. (4) For heat-insulation and high temperature protection purposes (e.g., for insulating roofs, chimneys, boilers, furnaces, steam piping, steam turbine bodies, tubes or pipes, ice-cupboards, and heat-insulated vans or wagons) in the form of fibres in bulk, nodules, felts, pads, casings (for pipes) or braids, (whether or not impregnated with glue, pitch or other substances, or with paper, textile or wire mesh supports). (5) For electrical insulation (e.g., for electric wires, cables or other current carrying apparatus) in the form of filaments, yarn, tape, braid, fabric (whether or not impregnated with natural resins, plastics, asphalt, etc.) and to reinforce PCB (printed circuit boards) used in the electronic industry (automatic data processing machines, phones, etc.). (6) For sound-insulation (e.g., for flats, offices, ships’ cabins, cars, theatres) in the form of fibres in bulk, felts, mattresses or rigid boards. (7) For the reinforcement of thermoplastic and thermoset in various production processes and for many applications such as tanks, vats and pipes for storing and transporting liquids, machine hoods and other moulded parts for industrial or agricultural use, bumpers for motor vehicles, equipment for track vehicles, railway coaches or aircraft, home appliances, boat hulls, fishing rods, skis, tennis rackets and other articles for sport, etc. (8) For the manufacture of miscellaneous other industrial products such as: filtration products for air-conditioning or for the chemical industry, reinforcement of grinding wheels, medical care, packaging reinforcement, etc.

The heading excludes :(a) Semi-finished products and articles obtained by compressing glass fibres, or superimposed layers of glass fibres, impregnated with plastics, if having a hard, rigid character and hence having lost the character of articles of glass fibres (Chapter 39). (b) Mineral wools (see Note 4 to Chapter 70) and articles thereof of heading 68.06. (c) Roofing boards with a substrate consisting of glass-fibre web or fabric completely enveloped in, or covered on both sides by, a layer of asphalt or similar material (heading 68.07). (d) Multiple-walled insulating glass with an interlayer of glass fibres (heading 70.08). (e) Optical fibre cables of heading 85.44, electrical insulators (heading 85.46) and fittings of insulating material (heading 85.47). (f) Optical fibres, bundles and cables of heading 90.01. (g) Dolls’ wigs of glass fibres (heading 95.03) and fishing rods made of glass fibres agglomerated with synthetic resin (heading 95.07). (h) Brushes of glass fibres (heading 96.03). Subheading Explanatory Notes. Subheading 7019.11

Chopped strand is produced by cutting strands containing many parallel filaments. Generally, chopped strands are used to provide strength, for example, to plastics or mortar or to different filters (air, oil, etc.).  |

Subheading 7019.12

A glass roving is a collection of parallel strands (assembled or multi-end roving) or parallel filaments (direct or single-end roving) assembled without intentional twist from glass fibre cakes (see hereafter) and usually without a cardboard tube.

The glass filaments obtained during the mechanical drawing process and wound under the bushings on flexible cardboard tubes are called "glass fibre cakes". These cakes of untwisted glass fibres are intermediate products, the further processing and classification of which depend on their filament diameter (in microns) and weight (in tex).

Glass fibre cakes with a filament diameter of not more than 14 microns and weighing 300 tex or less are light and thick fibres usually called "textile cakes" and designed to produce yarns and light flexible fabrics. These light and thick fibres are excluded from this subheading (subheading 7019.19).  |

Subheading 7019.13

This subheading includes slivers. A sliver consists of staple fibres of short lengths, usually less than 380 mm in length. The staple fibres are loosely arranged in parallel fashion into a rope-like strand with little or no twist (less than 5 turns per metre). Slivers are generally used to produce staple fibre yarn, but may also be used in the manufacture of wire and cable.

Yarn of this subheading is twisted, and of either continuous filament or staple fibre. Yarns are usually supplied either on plastic bobbins or on metallic warp beams.

They can be also texturised or voluminised. In this process the glass yarns are overfed in a nozzle in which an airstream creates turbulence that causes the formation of loops and imparts a slight (texturising) or high (voluminising) bulk.

These types of yarns are usually supplied on cardboard tubes and are used in various applications such as:

- wall covering woven fabrics to avoid a flat aspect,

- woven fabrics for roofing,

- thermal insulation products.  |

Subheading 7019.14

Mechanically bonded mats are flat reinforcing products of glass strands, consisting of several hundred parallel filaments. The glass strands are distributed in random order. In mechanically bonded mats the strands are stitched or needled together.

Glass strands retain their shape in the form of parallel filaments distributed randomly, which can be individually separated from the mat by hand, without damaging it. Subheading 7019.15

Chemically bonded mats are flat reinforcing products of glass strands, consisting of several hundred parallel filaments distributed in random order.

In chemically bonded mats the strands can be cut (mats of discontinuous strands) or uncut (mats of continuous thread) and are held together by means of a binder.

They retain their shape in the form of parallel filaments distributed randomly, which can be individually separated (after resolving a binder) from the mat by hand, without damaging it. Subheading 7019.61

Closed woven fabrics of rovings (no regular open structure) are interlaced by weaving on a loom and not coated or laminated. They usually have a weight of more than 200 g/m2 . They are mostly used for composites applications (e.g., wind energy, automotive industry). Subheading 7019.62

Other closed fabrics of rovings (no regular open structure), mechanically bonded, but not woven, mostly used for composites applications.

Binding is generally done by stitching, but can also be done by needling.

Typical products are multi axial fabrics, complexes or combinations (woven roving with chopped fibres of multi-end roving), which are multi-layer fabrics assembled together by stitching. Subheading 7019.63

Closed woven fabrics, plain weave, of yarns, not coated or laminated. These are used, for example, for covering walls or for thermal and acoustic insulation. Subheading 7019.64

Closed woven fabrics, plain weave, of yarns, coated or laminated (with silicone, PTFE, aluminium) are used for various industrial or building applications, for example:

- architectural use,

- smoke and fire protection Subheading 7019.65

Open woven fabrics of this subheading may include narrow open mesh fabrics having a regular "open" structure, for example in the shape of circles, ovals, rectangles (including squares), equilateral triangles or regular convex polygons, mechanically bonded. They are usually used for facade corner reinforcement or as joint tapes on walls.  |

Subheading 7019.66

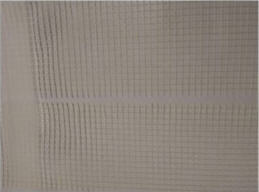

Open woven fabrics having a regular "open" structure, for example in the shape of circles, ovals, rectangles (including squares), equilateral triangles or regular convex polygons. These woven fabrics, are more than 30 cm wide and are usually used as reinforcement for facades in external thermal insulation composite systems, for marbles and mosaics, for gypsum boards, walls, and floors.

Light mesh fabrics with cell openings below 1.8 mm are usually used as insect screens or sun screens.

Heavy open mesh fabrics are usually called geotextile fabrics and are used for soil purposes such as reinforcement or slope stabilisation. Open mesh fabrics with a special resistant or silica glass coating are usually used for high temperature filtration or grinding wheel reinforcement.  |

Subheading 7019.71

Veils (thin sheets) are nonwovens made from individual glass fibres (filaments) distributed in random order. The fibres are held together by means of a binder and pressed and may or may not incorporate reinforcement threads which are most often stretched lengthwise throughout the sheets.

Unlike glass mats, the individual filaments of these products cannot be removed by hand without damaging the sheet.

Thin sheets can be distinguished from webs, mattresses and other insulation products by their regular thickness, which does not exceed 10 mm. Subheading 7019.72

Other chemically bonded closed fabrics may include complexes of woven roving with chopped fibres of multi-end roving, which are multi-layer fabrics assembled together by powder and thermal bonding. Subheading 7019.73

Other chemically bonded open fabrics may include laid scrims made of yarns (regular open structure).

|