|

40.01 ‑ Natural rubber, balata, gutta-percha, guayule, chicle and similar natural gums, in primary forms or in plates, sheets or strip.

This heading includes :(A) Natural rubber latex (whether or not pre‑vulcanised).

Natural rubber latex is the liquid secreted principally by rubber trees and, in particular, by the species Hevea brasiliensis. This liquid consists of an aqueous solution of organic and mineral substances (proteins, fatty acids and their derivatives, salts, sugars and glycosides) containing in suspension 30 % to 40 % of rubber (i.e., polyisoprene of high molecular weight).

This part includes : (1) Stabilised or concentrated natural rubber latex. Rubber latex tends to coagulate spontaneously a few hours after tapping; it must therefore be stabilised in order to ensure preservation and to prevent putrefaction or coagulation. This is usually done by adding ammonia to latex in the proportion of 5 to 7 grams per litre of latex, which produces a product known as "full ammonia" or FA type. A second stabilising method which produces "low ammonia" or LA type is to add a very small quantity (1 to 2 grams per litre of latex) of a low concentration mixture of ammonia and substances such as tetramethylthiuramdisulphide and zinc oxide.

There are also freeze‑resistant natural rubber latexes stabilised by the addition, in particular, of minute quantities of sodium salicylate or formaldehyde and intended for use in cold countries.

Natural rubber latexes are concentrated (mainly for transport purposes) by various methods (e.g., by centrifuging, evaporating, creaming).

The rubber content of commercial latexes is usually between 60 % and 62 %; higher concentrations are also found and in some cases the solid content may exceed 70 %. (2) Thermosensitive (heat‑sensitive) natural rubber latexes. These are obtained by adding heat‑sensitive agents. When heated these types of latexes gel faster than non‑thermosensitive latex. They are generally used for the manufacture of dipped or moulded articles or for the production of foam or sponge rubber. (3) Electropositive latexes. These latexes are also known as "reversed electric charge latexes", because they are obtained by reversing the charge of the particles of a normal concentrated latex. This is usually achieved by adding cationic surface‑active agents.

The use of such latexes counters the tendency of most textile fibres to resist rubber impregnation (because like ordinary latex, the electrostatic charge of the fibres in an alkaline environment is negative). (4) Pre‑vulcanised natural rubber latex. This is obtained by the reaction of vulcanising agents on latex under heat‑treatment at a temperature generally below 100 °C.

The rubber particles contained in the latex are vulcanised by adding an excess of precipitated or colloidal sulphur, zinc oxide and accelerators (e.g., dithiocarbamate). The degree of vulcanisation of the finished product can be altered at will, by varying the temperature, the heating time or the proportions of the ingredients used. Normally, only the outer walls of the rubber particles are vulcanised. In order to avoid over‑vulcanisation of the latex, excess ingredients are removed, by centrifugation, after heating.

The appearance of pre‑vulcanised latex is the same as that of normal latex. Their combined sulphur content is usually of the order of 1 %.

The use of pre‑vulcanised latex allows a number of operations (e.g., grinding, compounding)

to be by‑passed. It is used in the manufacture of dipped and cast articles (pharmaceutical and surgical goods) and, increasingly, in the textile industry and as an adhesive. It is also used in the manufacture of certain grades of paper and of composition leather, and gives a rubber having excellent electrical insulation properties (because of its low content of proteins and soluble substances).

Natural rubber latex is shipped either in internally coated drums (containing about 200 l) or in bulk. (B) Natural rubber in other forms.

For the purpose of this heading, the term "natural rubber" applies to Hevea rubber as traditionally shipped from the place of production, generally after it has been treated in plantation factories either for the purposes of transport and preservation or to give the natural rubber certain special characteristics which will facilitate its subsequent use or improve the quality of the finished products. To remain classified here, the rubber so treated must not, however, have lost its essential character as a raw material; further, it must not contain any added carbon black, silica or any other substance of a kind forbidden by Note 5 (A).

Coagulation of natural rubber latex takes place in tanks of various shapes, which may be fitted with movable partitions. In order to separate the rubber globules from the aqueous serum, the latex is coagulated by slight acidification with, for example, 1 % acetic acid or 0.5 % formic acid. At the end of the coagulation process the coagulum is removed either as slabs or as a continuous strip.

Subsequent treatment differs according to whether smoked sheets or pale or brown crepes, re‑agglomerated granules or free‑flowing powders are being produced. (1) Rubber sheets and crepes.

For the manufacture of sheets, the rubber strip is fed into a rolling mill in which the final set of embossed rolls leave the surface with characteristic markings (to facilitate drying by increasing the evaporation area). As the rubber strip (about 3 to 4 mm thick) emerges from the mill it is sliced into sheets. These are then placed in either a drying shed or a smoke house. The purpose of smoking is to dry the rubber and to impregnate it with creosotic substances which serve as anti‑oxidants and antiseptics.

For the manufacture of pale crepe, the rubber coagulum is fed into a battery of creping machines. The first machines have grooved rollers whereas the last machines have smooth rollers, rotating at different speeds. This operation takes place under a constant stream of water so that the rubber is thoroughly washed. It is then dried, at room temperature or in hot air, in a ventilated drying shed. Two or more plies of crepe may be superimposed to form slabs of sole crepe.

Sheets are also made by the following process : after the latex has been coagulated in cylindrical tanks, the coagulum is sliced, by sawing, into a long strip which is cut into sheets and dried (generally without smoking).

Some types of rubber (in particular crepe other than pale crepe) are not manufactured directly by the coagulation of latex, but are produced by the subsequent re‑agglomeration and washing in "creping machines" of the coagula obtained during tapping or factory processing. The resulting sheets, of varying thicknesses, are dried in the same way as pale crepe.

Natural rubber as described above is usually marketed according to its appearance in the forms and grades corresponding to international standards set up by the concerned international organisations.

The most common types are smoked sheets and cuttings thereof, pale crepes and cuttings thereof, brown crepes and ribbed and air dried sheets. (2) Technically specified natural rubber (TSNR).

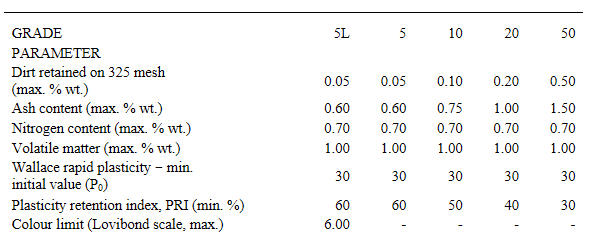

This is dry raw natural rubber which has been processed, tested and graded into five general grades (5L, 5, 10, 20 and 50) according to the specifications in the following table :

Table : Grade of TSNR and maximum allowable limits for each parameter  |

TSNR must be accompanied by a test certificate, issued by the competent authorities of the producing country, specifying the grade, specifications and test results of

the rubber. Certain producing countries may have grades with more stringent specifications than those stated in the table above. TSNR is packed in bales of

33 1/3 kg and wrapped in polyethylene. Normally 30 or 36 such bales are either palletised and covered by polyethylene liners on the inside or shrink‑wrapped with polyethylene. Each bale or pallet has specific markings to show the grade, weight, producer code, etc.(3) Re‑agglomerated rubber granules.

The techniques used for processing granulated rubber are designed to give cleaner products with constant properties and a better appearance than rubber sheets or crepes.

The manufacturing process comprises granulation of the coagulum, particularly thorough cleaning, drying and compression into bales. A wide range of machines may be used for granulation, such as rotary blade choppers, cross hammer mills, pelleting machines and creping machines. The purely mechanical action of these may be reinforced by the addition of very small quantities (0.2 to 0.7 %) of castor oil, zinc stearate or other crumbling agents, incorporated in the latex before coagulation. These crumbling agents have no effect on the subsequent use or properties of the rubber.

The granules are dried in semi‑continuous trolley‑type dryers, conveyor belt tunnel dryers or extruder‑dryers.

The dried granules are finally compressed, under high pressure, into parallelepipedal bales weighing from 32 to 36 kg. Re‑agglomerated rubber granules are usually sold with guaranteed technical specifications. (4) Free‑flowing powders of natural rubber.

These are prepared as indicated in paragraph (3) above but without compression.

In order to prevent the granules from re‑agglomerating under the action of their own weight, they are blended during preparation with powdered inert substances such as talc or other anti‑tack agents.

Rubber powders can also be obtained by injecting into the drying chambers, with the latex, an inert substance, such as siliceous earth, expressly to prevent agglomeration of the particles. (5) Special types of natural rubber.

Various special types of natural rubber can be obtained in the forms described in (1) to (4) above. The principal types are : (a) CV (constant viscosity) rubber and LV (low viscosity) rubber.

CV rubber is obtained by adding a very small quantity (0.15 %) of hydroxylamine before coagulation and LV rubber by adding, also before coagulation, a small quantity of mineral oil.

The hydroxylamine prevents the spontaneous increase in the viscosity of the natural rubber during storage. Use of these rubbers enables manufacturers to forecast mastication periods. (b) Peptised rubber.

This is obtained by adding to the latex, before coagulation, approximately 0,5 % of a peptising agent, which reduces the viscosity of the rubber during the drying operation. This rubber accordingly requires a shorter period of mastication. (c) Superior processing rubber.

This is obtained either by coagulating a mixture of ordinary and pre‑vulcanised latex or by mixing natural latex coagulum with pre‑vulcanised latex coagulum; its use makes extrusion and calendering easier. (d) Purified rubber.

This is obtained without addition of foreign substances, by a variation of the normal process of rubber production, for example, by centrifuging the latex.

It is used in the preparation of chlorinated rubber and in the manufacture of certain vulcanised goods (electric cables, etc.) whose properties would suffer from the presence of the impurities normally contained in rubber. (e) Skim rubber.

This is obtained by coagulating the by‑product of latex skim. (f) Anticrystallising rubber.

This is obtained by adding thiobenzoic acid to latex before coagulation; it thus becomes freeze‑resistant. (C) Balata.

Balata gum, or balata, is extracted from the latex of certain plants of the Sapotaceae family, especially from the bullet‑tree (Manilkara bidentata) found mainly in Brazil.

Balata is a reddish product, mostly shipped in blocks weighing up to 50 kg, but sometimes also in sheets from 3 to 6 mm thick.

It is mainly used for the manufacture of conveyor or transmission belts or belting. It is also used, mixed with gutta‑percha, in the manufacture of submarine cables and of golf balls. (D) Gutta‑percha.

Gutta‑percha is extracted from the latex of various trees of the Sapotaceae family (e.g., of the genus Palaquium and the genus Payena).

It is yellow or yellow‑reddish. According to its origin, it is shipped either in cakes weighing 0.5 to 3 kg, or in blocks of 25 to 28 kg.

In addition to its uses, when mixed with balata, in the manufacture of submarine cables, golf balls and belting, it is also used for making sealing rings for pumps or valves, flax spinning rollers, linings for tanks, bottles for hydrofluoric acid, adhesives, etc. (E) Guayule gum. This is extracted from the latex of the Parthenium argentatum, a shrub originating in Mexico.

Guayule rubber is generally shipped in cakes or sheets. (F) Chicle gum. This is extracted from the latex contained in the bark of certain trees of the Sapotaceae family grown in the tropical regions of America.

This gum is reddish, and is generally shipped in cakes of various sizes or in blocks weighing about 10 kg.

It is mainly used for the manufacture of chewing‑gum. It is also used for the manufacture of certain surgical tapes and of dental goods. (G) Similar natural gums, for example, jelutong.

In order to be classified in this heading, these gums must be rubber‑like in character. (H) Intermixtures of any of the foregoing products.

This heading excludes :(a) Intermixtures of any product of this heading with any product of heading 40.02 (heading 40.02). (b) Natural rubber, balata, gutta‑percha, guayule, chicle and similar natural gums, compounded, before or after coagulation, with substances forbidden by Note 5 (A) to this Chapter (heading 40.05 or 40.06).

|